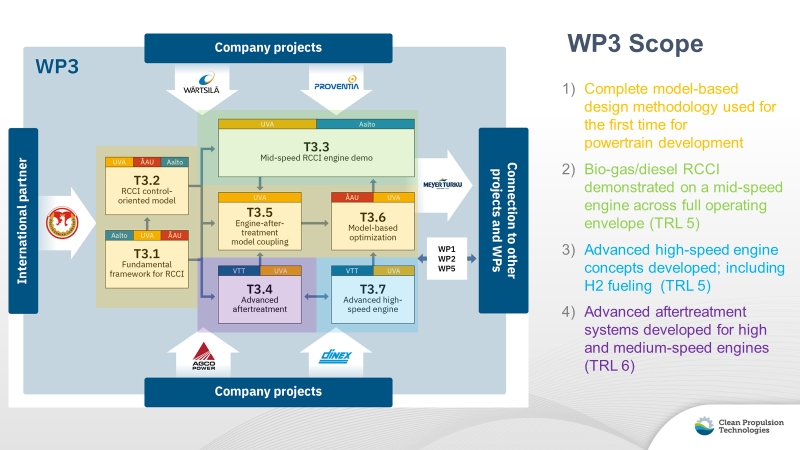

Due to the exceptional energy density requirements, combustion engines will remain the prime mover for gross of marine and off-road applications. WP3 aimed to respond to the pressing need to develop market-feasible solutions to mitigate climate impact of combustion-based powertrains. The objective was to create a portfolio of high technology readiness level (TRL 5-6) engine-aftertreatment systems that allow a min 30% GHG reduction with ultra-low NOx and PM emissions, on a tank to wheel basis. The primary challenge was to handle the immense calibration and control complexity brought by these next generation solutions. To this end, the tasks in the centerline of Figure 1, committed to developing an accelerated model-based design methodology that was used for the first time on such a scale to develop new combustion and aftertreatment platforms. This methodology commonly supports the fast-tracking innovative solutions for mid-speed engines and high-speed engines, elaborated in tasks T3.3 and 3.7 respectively.

Figure 1. Main tasks for CPT – WP3 including responsible project partners.

The methodological advancements introduced by the project’s model-based framework involve two unique toolchains referred to as UVATZ. The fully physics-based UVATZ-MZ (multi-zone) code allows to keep the predictive features of full-fidelity reactive CFD simulation with 10000 times accelerated runtimes. UVATZ-RT (Real-time) – a linearized version of UVATZ is even faster, matching the time scale of the physical combustion process (0.3 ms per cycle).

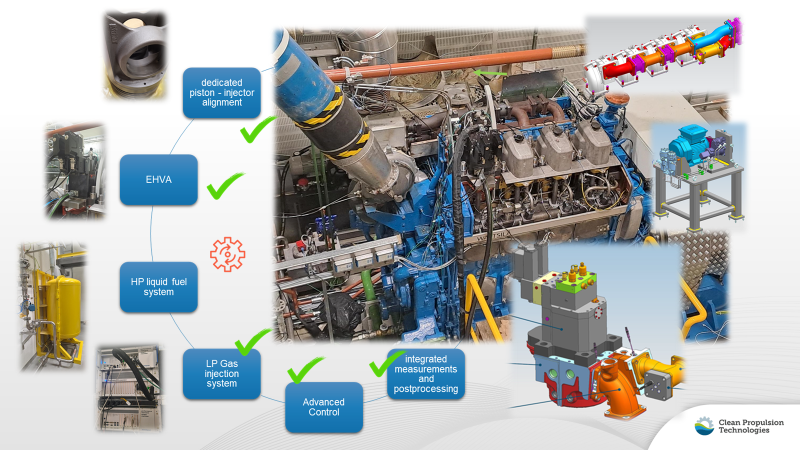

These new models have been tested in the project for compatibility with commercial engine simulation software to enable integrated engine-aftertreatment system design and interfacing with complete vehicle-level simulation. The whole innovative model-based development framework has been applied to the rapid prototype of a new ultra-clean and ultra-efficient (52% target brake efficiency) marine engine operating in RCCI (Reactivity Controlled Compression Ignition) mode. The modeling assumptions have been positively verified in 2 separate RCCI technology demonstrator platforms based on Wartsila 20 and 31 medium-speed dual-fuel engines. The demonstrators involve a handful of enabling technological innovations like fully variable electro-hydraulic valve actuation (EHVA), fast thermal management and closed-loop, model-based combustion control.

Figure 2. Medium-speed W20-RCCI cyclops engine at VEBIC laboratories (public RCCI engine demonstrator developed in Task 3.3)

A similar model-based methodology has been used to prototype an innovative off-road hydrogen engine. The hydrogen platform based on the next-generation CORE engine family from AGCO Power which accommodates lean-burn principle and direct hydrogen injection underwent successful calibration tests in Task 3.7 proving zero-greenhouse gas emissions with very low NOx emissions over wide operation area.

Other technologies tested for high speed off-road engines involve variable valve actuation for efficient aftertreatment thermal management. These were developed along with novel aftertreatment configurations (double SCR on filter) and innovative regeneration strategies for SCR and DPF components to provide conformity with the upcoming ETA Tier V emissions legislation for non-road mobile machinery.

WP3 has produced over 20 scientific publications. The publications provide a detailed insight into the mechanisms responsible for the emission/efficiency benefits enabled by the technologies, and provide an outlook that supports the essential role of combustion-based propulsion for the next generation marine and off-road applications.

Maciej Mikulski

Professor, University of Vaasa

Project leader and WP3 leader of Clean Propulsion Technologies

WP3 research team