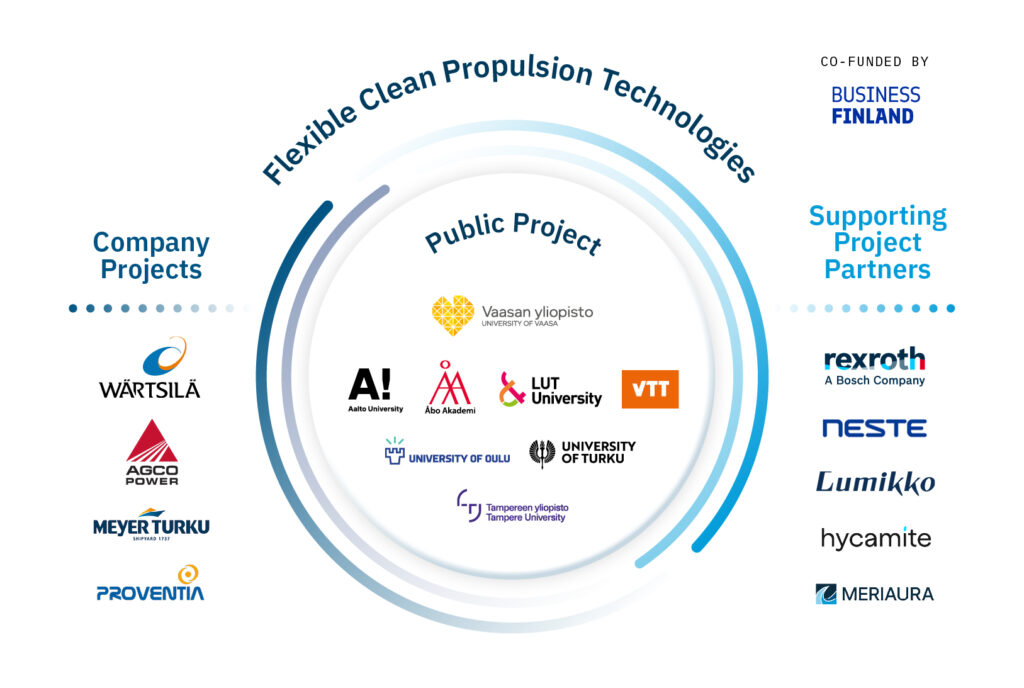

The Flexible Clean Propulsion Technologies project consortium comprises 17 partners (eight research organisations and nine companies) managed by the University of Vaasa to form a common co-innovation project. The consortium is further strengthened by close cooperation with 12 international partners. One of the consortium’s main strengths is that its constituent organisations supplement each other’s expertise and are capable and willing to cooperate to achieve a common goal. Each partner has a clear role in the consortium.

The consortium builds on groundbreaking development of the previous project, Clean Propulsion Technologies, which allowed Finland to embrace a leadership role in powertrain solutions for marine transport and off-road machinery.

Research organisations

The public project part is formed by eight national universities and research institutes, with complementary expertise in various domains of propulsion technology. University of Vaasa acts as consortium coordinator, leads the multi-fuel research in WP3 and is spearheading the development of the marine engine platform in WP1. University of Vaasa’s prototyping methods and predictive physics-based models are used in all other work packages. VTT Finland leads the heavy-duty engine development in WP2 and provides enabling solutions for the aftertreatment and hybrid tracks. University of Oulu is our expert on catalytic materials and leads the multi-fuel aftertreatment development in WP4. LUT University, supported by Tampere University, take responsibility for the hybrid track in WP5. Aalto University drives single-cylinder engine experiments for WP2 and provides computational fluid dynamics (CFD) simulation support for the project. Together with the University of Turku, they are providing the bulk of Flex-CPT smart control solutions. The consortium is completed with Åbo Akademi University, driving the life cycle analysis (LCA) in WP3 and developing accelerated design of experiment (DOE) methods for WP1. Each of the research organisations has their own sub-project integrated with the public research plan.

Companies

The Flex-CPT collaboration model is based on the innovative idea that Finnish powertrain original equipment manufacturers (OEMs) in the off-road and marine sectors can together form a critical mass in research and development to compete on a global scale. Two industry leaders, Wärtsilä and AGCO Power, provide complete propulsion solutions for the marine and off-road sectors, and they form the company backbone of the consortium. Proventia is contributing to the coordinated powertrain development framework with aftertreatment solutions. Co-development of work in the fuel-engine-aftertreatment field is reinforced by Neste – leader in renewable fuel production. Competence in hydrogen storage and logistics is provided by Hycamite. Complementary hybridisation solutions are co-developed with support of two OEMs, Bosch Rexroth and Lumikko, suppliers of electro-hydraulic components and energy management systems. Shipbuilder Meyer Turku acts as the propulsion system integrator, and brings the solution to vessel-level applications, together with the shipping line Meriaura.

Wärtsilä, AGCO Power, Meyer Turku and Proventia will carry out their own company sub-projects. These will be strongly linked to Flex-CPT’s public research by the common scope and multi-layer interactions.

International collaboration partners

The Flex-CPT consortium benefits from the knowledge and input of 12 renowned international research institutes with key expertise in complementary areas of research. Each has an explicitly defined role in the common plan. International collaboration partners are: Lund University (Sweden); Politecnico di Torino (Italy); Arizona State University (USA); Karlsruhe Institute of Technology / Institute for Vehicle Systems Engineering (Germany); University of Cyprus (Cyprus); Université Claude Bernard Lyon (France); Wuhan University of Technology (China); Lublin University of Technology (Poland); Hitit University (Türkiye); IEA AMF TCP (International Energy Agency Technology Collaboration Platform on Advanced Motor Fuels); University of Agder (Norway); Korea Advanced Institute of Science & Technology – KAIST (South Korea).

Main financier

This project strengthens the forerunner position for Finland’s maritime and off-road expertise in terms of combustion engine development towards emission-free and flexible operation. The cooperation between research institutes and companies creates a strong basis towards commercial breakthroughs in global markets.

Kari Kuokkanen, Chief Funding Advisor

Tero Ijäs, Ecosystem ManagerPartners

Industrial project partners

We acknowledge that effective decarbonisation means embracing all new zero-carbon fuel options, like hydrogen and ammonia, alongside more mature low-carbon choices such as methane, methanol and bio- and renewable diesels. This level of multi-fuel integration is an unparalleled technological challenge for powertrain development.

Maciej Mikulski

Professor, Project Leader of Flexible Clean Propulsion TechnologiesBy partnering with Flexible Clean Propulsion Technologies project, Wärtsilä is taking a significant step towards realizing our Zero Emission Marine vision. The consortium’s expertise in flexible, clean propulsion technologies will support the industry in meeting its 2030 and 2050 emission reduction goals, ensuring a greener future for the maritime sector.

Jonas Åkerman

Director, Research & Technology DevelopmentIn addition to the development of new solutions, research-oriented co-operation with companies and universities having the same vision has significant advantages in sharing knowledge and developing expertise. Collaboration improves export opportunities, increases competitiveness, and strengthens technology leadership.

Kari Aaltonen

Director, EngineeringMeyer Turku has long been committed to develop cruise ships with higher energy efficiency and lower emissions. Modern cruise ships operating in varying conditions, profiles and areas, require a lot from the powertrain technology and ship integration to reach true net-zero operation. The Flexible Clean Propulsion Technology project is one of the key projects to reach Meyer Turku’s goal to develop a climate-neutral ship concept.

Wilhelm Gustafsson

Team Leader, Energy EfficiencyThe content of Flexible Clean Propulsion Technologies aligns with VTT´s objective to accelerate the sustainability and decarbonisation in marine and NRMM sectors. We at VTT are very enthusiastic to be involved in the Flex-CPT consortium, and through the project we aim to investigate new hydrogen and methanol powertrain solutions and develop methods which increase the efficiency of relevant exhaust reduction technologies and to explore future multi-fuel and hybrid solutions.

Rasmus Pettinen

Senior ScientistProventia’s vision is zero emissions, and within this project we develop methods to cut NOx emissions from off-road machines to an ultra-low level. Our aim is to develop high-performing and flexible exhaust aftertreatment for different low-carbon fuels, applications and engine technologies. Flexibility needs to be met across wide operating conditions and different customer requirements, keeping CO2 and NOx emissions at an ultra-low level.

Arno Amberla

Director, Technology, Emission ControlSupporting project partners

Neste creates solutions for combatting climate change and accelerating a shift to a circular economy. Decarbonising marine and off-road transportation is an important target which requires collaboration along the value chain. With Flex-CPT consortium, we want to be part of that value chain, creating solutions and establishing mutually beneficial partnerships committed to sustainability.

Sari Kuusisto

Senior Associate SustainabilityBosch Rexroth innovates in mobile work machines, emphasising technology and engineering. Bosch Rexroth’s expertise in hydraulics, electric drives and controls ensures high-performance, efficient and reliable systems. Committed to advancing the field, Bosch Rexroth is a trusted partner for companies aiming to lead the market. With initiatives like Flexible Clean Propulsion Technologies, Bosch Rexroth focuses on improving fuel efficiency, productivity and safety, driving the industry forward and shaping the future of mobile work machines.