VIRTUAL SENSORS

Virtual sensors are used to indirectly estimate the values of physical variables that cannot be measured directly or for which the use of a direct measurement device is undesirable (an expensive device, change of measurement accuracy due to wear and tear etc.) Virtual sensors have high potential in analysis of complicated systems, and in controlling them.

The research of Virtual sensors was used for estimation of engine cylinder pressures and emissions (Nitrogen oxides NOx, Carbon oxides COx). The target has been to construct emission estimates to be utilized in the development of new low emission combustion methods. These include the modelling and control of low-temperature combustion engines and input NOx estimation of engine purification units (Selective catalytic reduction, SCR).

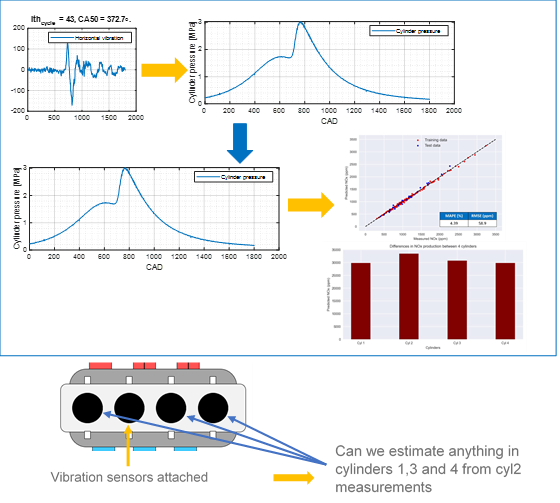

The applied technique is illustrated in the above figure. A vibration sensor has been attached to the cylinder head of the engine. Multi-Layer Perceptron and Radial Basis Function networks are used to construct and estimate of the cylinder pressure, and Principal Component Analysis (PCA) is thereafter used to construct estimator algorithms for NOx and COx emissions. Algorithms can be modified to include the emission estimation of several cylinders, which have influence on each other.

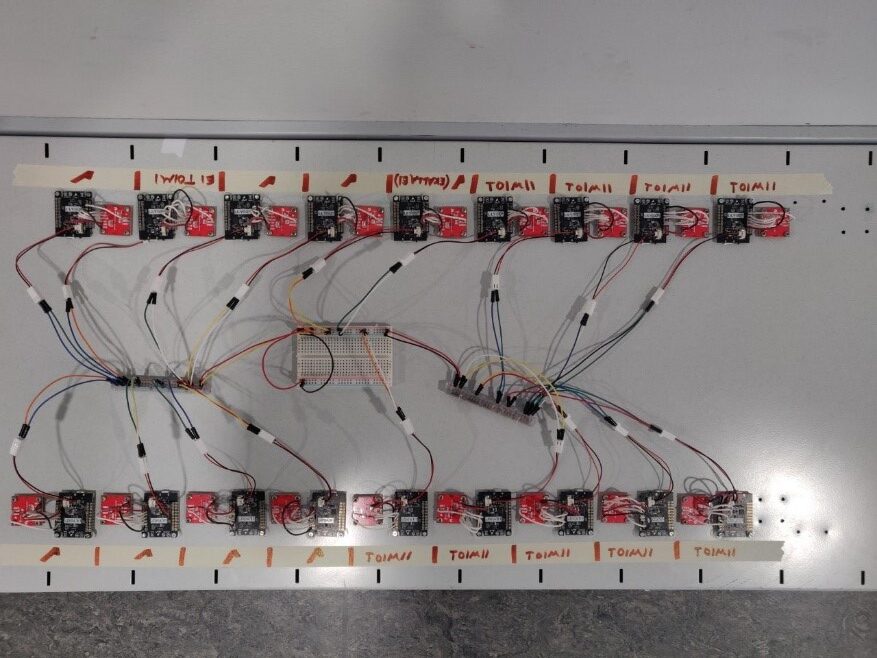

In another part of the project a virtual sensor network was constructed as a project work of three master level students. The constructed pilot system (see figure below) consists of 18 vibration sensors, each connected to a microcontroller and then through a WiFi connection to a router, which collects the data for further processing. The sampling frequency of 10 kHz makes the data exchange in the system extremely challenging, and the telecommunication and data storage/transmission without losing data packets have been the most difficult issues to deal with. The project was proposed by Wärtsilä, the idea being to use this kind of system for “easy” measurement of engine vibrations by just attaching sensors on the engine. The pilot system is extremely interesting and is currently being developed further internally in Wärtsilä.

MODELLING AND CONTROL OF LOW TEMPERATURE COMBUSTION

This part of research was carried out in close co-operation with the University of Vaasa, Work package 3. The Reactivity Controlled Compression Ignition (RCCI) is a combustion method which operates in low cylinder temperatures and leads theoretically to zero NOx emissions. It is a dual fuel concept in which low reactivity and high reactivity fuels are injected into the cylinders, which leads to shaped combustion start due to complicated chemical reactions. These kinds of new low temperature and low emission combustion methods can lead to a new era of combustion engines for the future, which can meet the needed power density demands of large engines in the marine and off-road sector with very low emissions.

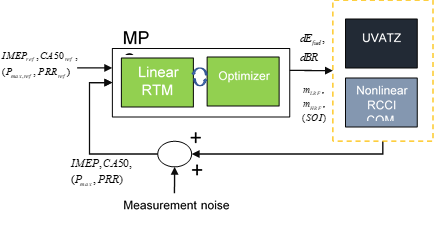

The below figure shows the topology used in RCCI control. The accurate physico-chemical model of the RCCI process (the UVATZ model) has been used to construct an approximative linear Real Time Model (RTM), to be used in the construction of adaptive Model Predictive Control MPC) algorithm to control the fuel injections (time and amount of fuel) to the engine. Adaptive means that the process model parameters are continuously estimated and used in the Receding Horizon estimator of the MPC. The control input is calculated by minimizing a cost function. In order to “close the loop” for simple and fast simulation another simplified process model called COM (Control Oriented Model) was designed by using MKIM (Modified Knock Integral Model) and Wiebe functions to model the combustion dynamics and timing faster than UVATZ but still at a good accuracy. The main variables to be controlled in the cost function were the Indicated Mean Effective Pressure (IMEP) and the time where 50 per cent of the fuel has been burned (CA50). The MPC controller was tested by using both the UVATZ model (simulation taking a long time) and COM model as the process model, controlled by the MPC designed by the RTM model. The results were very similar and good. However, for final validation practical tests with a real engine are needed.

Kai Zenger

Principal University Lecturer, Aalto University

WP2 leader of Clean Propulsion Technologies

WP2 research team