Work Package 2 of the Clean Propulsion Technologies project develops efficient new algorithms for estimation of engine emissions by indirect measurements, for solving optimization problems for ship routing under varying environmental conditions, and for developing new model predictive control algorithms for new combustion and purification technologies.

Docent Kai Zenger works as Senior University Lecturer of Automation Technology at Aalto University School of Electrical Engineering. Zenger received the M.Sc., L.Sc., and D.Sc. degrees in electrical engineering, computer technology, and automation and systems technology in 1986, 1992, and 2003, respectively. From 1983 to 1989 he worked as an automation engineer in the industry. Since 1989 he held several positions related to teaching and research in the Control Engineering Laboratory at Helsinki University of Technology. Zenger’s main research areas are Control Engineering and System Theory generally, with applications in chemical process engineering, electrical engineering, power electronics, and mechanical engineering. He has specialized in the research of time-varying linear systems, periodic systems, and adaptive and robust control methods.

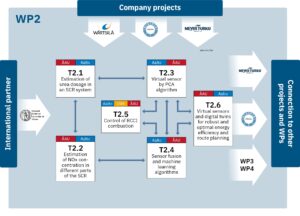

Zenger is leading the CPT project’s WP2. The research done in the WP covers a broad area and Zenger describes his role more as a coordinator than a leader. The key players in the work package’s six tasks consist of three companies (Wärtsilä, Napa, Meyer Turku) and three universities (Aalto University, Åbo Akademi University, and The University of Vaasa).

According to Zenger, the most innovative and inspiring thing in WP2 is the possibility to develop intelligent methods and algorithms that help produce environmentally friendly and energy saving new technological solutions for the future.

WP2 has connections to all the work packages of the project, especially WP3 ‘Novel combustion and advanced aftertreatment’ and WP4 ‘Multiple power source propulsion’. Virtual sensors, which estimate physical variable values by using indirect measurements are extremely important in a wide application area.