INTRODUCTION

To comply with the decarbonisation targets, radical change is needed. One of the challenges is fuel and the related global investments in its production and infrastructure. Wärtsilä is leading the way in developing a wide range of fuel technologies to help navigate the route to reduced greenhouse gas emissions – whatever fuel is chosen.

STRIVING FOR LOWER EMISSIONS

Before we begin discussing future fuels, an important distinction should be made between so-called ‘carbon-neutral’ and ‘zero-emission’ fuels.

- Carbon-neutral fuels are those that have no net carbon emissions, meaning their production and use does not increase the amount of CO2 in the atmosphere. Examples include synthetic fuels made with renewable energy and certain biofuels.

- Zero-carbon fuels release no CO2 when used as they do not contain any carbon. While hydrogen is an example of a zero-carbon fuel, it may or may not be carbon neutral depending on how it was produced.

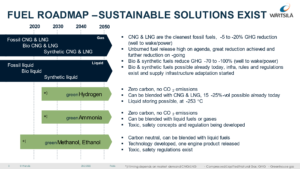

Wärtsilä is investigating a wide range of fuels (fig 1), including bio and synthetic liquefied natural gas (LNG) and natural gas along with ammonia, methanol/ethanol, hydrogen and biofuels. Wärtsilä’s research draws on deep experience gained through decades of building engines as well as supply and storage systems for a wide range of fuels.

When moving towards a complex fuel future, Wärtsilä’s goal is simple: to continue to be a provider of complete solutions for all available future fuels. Given the market demand, in the next decade we will commercialise engine technologies that will allow to make use of all fuels currently under discussion. Given the modularity of modern engines this means also that owners can already today plan how to use new fuels when they become available.

Fig 1. Fuel roadmap – focusing on renewable fuels

A FOCUS ON LNG – AND FUEL FLEXIBILITY

There are uncertainties around every prospective fuel, including when and where they will be available and at what price. Building on fuel flexibility, and where appropriate, retrofitting powerplants and older ships – offers a hedge against these risks.

To start with, Wärtsilä believes that the transition to clean fuels will be easiest, most cost effective and fastest for those power plants and ships powered by NG/LNG, which already offers GHG emission reductions of between 5 and 20% compared to heavy fuel oil, calculated on the well to power/wake value chain. Bio and synthetic NG/LNG can be used initially as drop-in fuels alongside conventional NG/LNG to reduce carbon content and later, as supply increases, to replace conventional NG/LNG entirely. Additionally, this solution requires only existing infrastructure, minimising the amount of investment needed. Bio NG/LNG also has the big advantage that it can be produced using many kinds of sustainable feedstocks, from manure via sewage residue to forest residue and many other types of waste.

Other alternative fuels might take between 10 and 20 years to be available, considering the time required to develop reliable, global fuel supply, infrastructure and bunkering facilities. However, NG/LNG is not a perfect solution – methane leakage during production and combustion is still a challenge that negatively impacts the GHG footprint of NG/LNG. Nevertheless, over the last 25 years we have reduced methane slip by 85% and are continuing to reduce it further with new combustion technologies.

EXPLORING MANY ALTERNATIVE FUELS

There are many fuels that can be used in reciprocating combustion engines. These are the main candidate fuels for the future in addition to NG/LNG and liquid fuels:

HYDROGEN

Wärtsilä already has a strong understanding of hydrogen, and our dual-fuel (DF) engines and spark-ignited (SG) gas engines can already operate with fuel blends of hydrogen in NG/LNG comprising of up to 25%-vol Hydrogen, further highlighting the flexibility of our engines. We started with using hydrogen in our gas engines in 2015 and are continuing development towards a pure hydrogen engine. Fuel distribution, storage and supply remain a challenge for hydrogen due to its low volumetric energy density. The current hydrogen supply is fossil based so in future it would have to be made in an environmentally sustainable way i.e. by electrolysis of water to hydrogen and oxygen by using renewable electricity. Synthetic hydrogen will take around a decade to be globally and reliably available.

AMMONIA

The exploration of ammonia as a fuel is progressing fast. It has several advantages over hydrogen, for example its greater energy density and the fact that it does not need to be stored under compression or at very low temperatures. Ammonia is toxic and highly corrosive, making it challenging to handle. Furthermore, the current ammonia supply is fossil based so in future it would have to be made in an environmentally sustainable way with synthetic hydrogen and nitrogen.

Wärtsilä is not starting from scratch in this area. We have several years’ experience of designing cargo-handling systems capable of handling ammonia for use on LPG carriers. We have performed combustion tests with ammonia in our fuel laboratory, and have now taken the step to full-scale Proof of Concept type technology development tests.

METHANOL / ETHANOL

Until now, methanol/ethanol has not been widely used as a fuel. This easily and cheaply produced industrial alcohol is today made predominantly from natural gas, but the use of hydrogen from renewable electricity and recaptured carbon to make green methanol/ethanol would make it carbon neutral. And with better combustion and easier storage and handling than ammonia, methanol/ethanol is a key component of decarbonisation in the maritime industry.

Only a few marine engine builders have experience with methanol engines. A project to convert a Wärtsilä Z40 engine on the ro-pax vessel Stena Germanica to burn methanol started operation in 2015. The engine now can run on methanol, and the success of the installation has inspired Wärtsilä to investigate this fuel further.

BIODIESEL

Fuels derived from biomass have great potential as a carbon-neutral energy source. They can be made in a variety of forms that can be used in both diesel and gas engines, either as a drop-in fuel or as a standalone fuel. As biofuels are compatible with existing engine, fuel supply and storage technologies they could offer simple and capital efficient decarbonisation of shipping.

Mikael Wideskog

Director, Sustainable Fuels & Decarbonisation

Wärtsilä Marine Power Supply,

R&D and Engineering