One of the first tasks in the Clean Propulsion Technologies project, Task 2.1 “Estimation of urea dosage in an SCR system”, has been successfully completed. The task was led by Åbo Akademi University and it is part of Work Package 2 “Virtual sensors and control”. We are happy to share some findings from T2.1 below.

Measurements come with a cost, and they can be unreliable. In today’s digital world, you should always look for opportunities for replacing or complementing the measurements with estimation. The latter means the use of models, that is digital twins, and often secondary simpler, cheaper and more reliable measurements. This is one of the topics in the Clean Propulsion Technologies project.

- Estimation of inputs to the system is a key technology. This is a bit more difficult than estimation of system internals (that is states), but we have come to the conclusion that it can be done, on real and nonlinear systems. A link to an earlier study on input estimation.

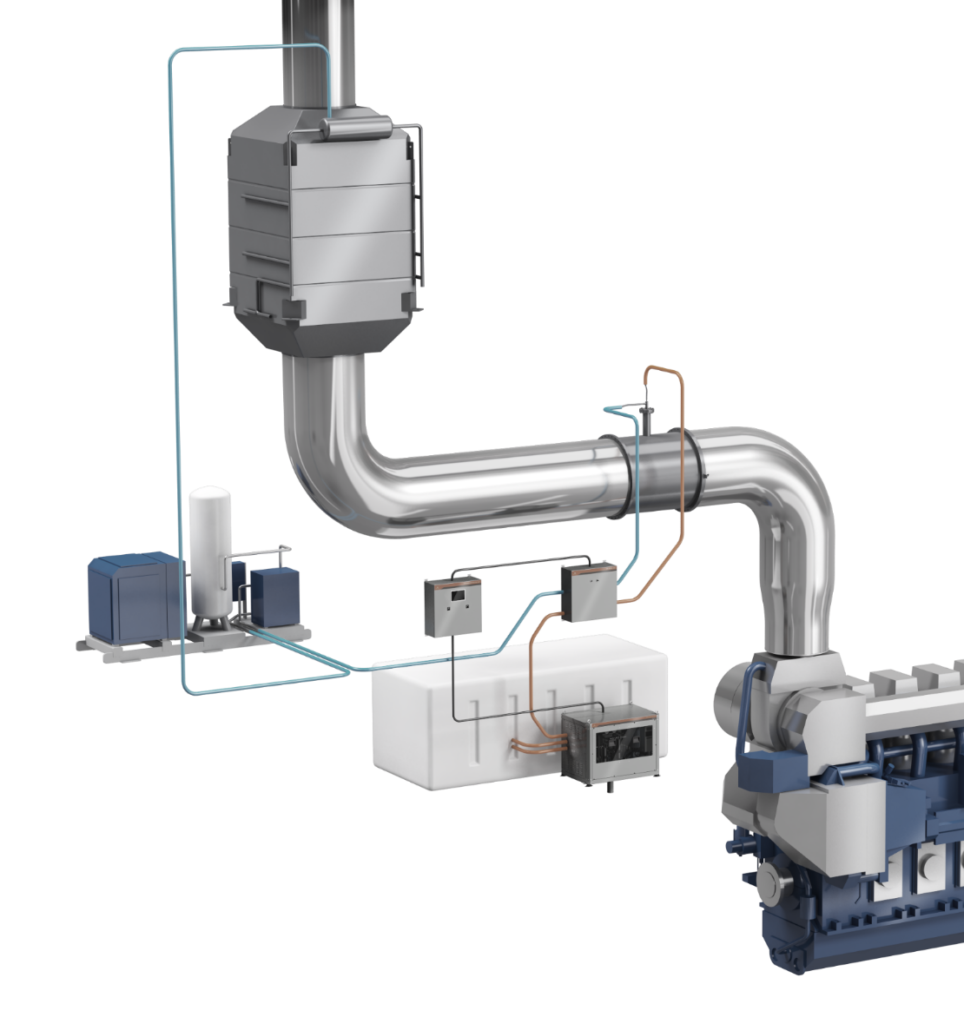

- In this case, we studied how to make urea dosing to selective catalytic reduction more accurate, which in turn leads to reduced emissions.

- System design matters. You do need the digital twin for the estimation, and if you do the design such that the system becomes simpler to model, your estimation will become more reliable.

For example, a flow can be controlled with a valve, which is not that simple to model, due to various nonideal and nonlinear phenomena associated with valves. If you replace the valve with a frequency converter on the pump instead, it becomes much simpler to model, and it might be possible to replace the flow measurement with an estimator. Furthermore, measurement of small flows can be difficult, while frequency converters convey accurate information of the frequency over the whole range. On top of that, the frequency converter does also save energy, and thus the environment, and such win-win arguments do help you to motivate the investments needed.

The project team behind this consisted of Ludvig Sandell, Mikael Manngård and Jari Böling from Åbo Akademi University, and Johan Frants, Markus Hanhisuanto and Jan Torrkulla from Wärtsilä.