The electrification of non-road mobile machines is a key step toward reducing emissions and improving energy efficiency in sectors such as construction, agriculture, mining, and material handling. As these machines increasingly rely on batteries, managing battery temperature becomes a central challenge. High and uneven temperatures can affect safety, reliability, and lifetime, especially under the highly dynamic and demanding operating conditions typical of non-road applications.

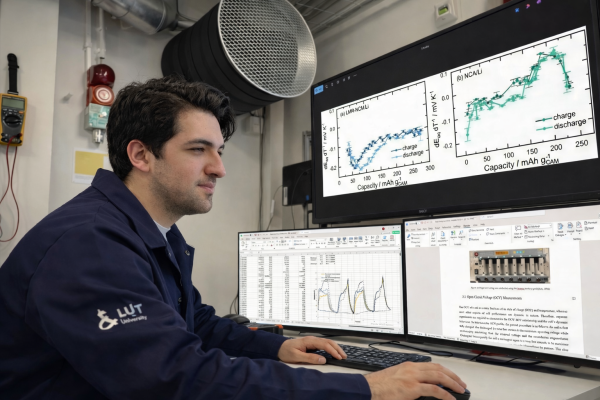

This challenge forms the background of the Master’s thesis of Shruthi Meda at LUT University. In her work, Shruthi studies passive thermal management of lithium-ion battery modules for non-road mobile machines, focusing on the use of phase change materials to control battery temperature. The thesis builds on her academic background in Electronics and Communication Engineering, her professional experience as an electronics component engineer, and her Master’s studies in Electric Transport Systems at LUT University.

In her thesis, Shruthi investigates the use of phase change materials (PCM) as a passive solution for controlling the temperature of lithium-ion battery modules used in non-road mobile machines. To explain the idea in simple terms, PCM can be seen as a wax-like substance that absorbs excess heat by melting when temperatures rise, without the need for fans, pumps, or external power. This allows batteries to remain within safe operating temperatures during intense use. The thesis was carried out at LUT University and supervised by Prof. Pertti Kauranen (LUT University) and Prof. Arunachala Nadar Kannan (Arizona State University).

The research was conducted as part of the Flexible Clean Propulsion Technologies (Flex-CPT) project, which explores technologies and system-level solutions that support cleaner propulsion and energy systems. More specifically, the thesis aligns with Flex-CPT work related to efficient thermal management in electrified and hybrid non-road machinery, particularly within the work package focusing on thermal innovations. By providing experimental data on PCM-based passive cooling for battery modules, the work supports the project’s goals of developing energy-efficient, compact, and reliable powertrain solutions while reducing reliance on complex active cooling systems.

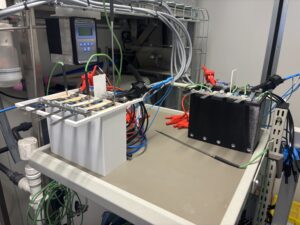

At the core of the thesis is a practical question: how effective can passive thermal management be for battery modules operating under realistic non-road duty cycles? To answer this, Shruthi designed and experimentally tested custom-built 2S2P lithium-ion battery modules, both with and without PCM. The modules were subjected to controlled charge–discharge conditions and non-road transient cycles, allowing a direct comparison of thermal behaviour under operating scenarios that resemble real non-road machine usage.

One of the key outcomes of the thesis is a clear comparison of how battery temperatures behave under different operating conditions. Under moderate use, the battery module with phase change material (PCM) performed similarly to a conventional module. However, under more demanding conditions that better reflect real non-road operation, the PCM showed clear benefits by limiting peak temperatures and helping the battery heat up more evenly. Even during repeated demanding cycles, the PCM-equipped module remained thermally stable without signs of overheating.

Beyond these results, the thesis also improves understanding of how heat develops and spreads inside a battery and how PCM helps control this process. Seeing the battery temperature stabilise in real time during challenging test cycles was particularly rewarding and demonstrated the practical potential of passive cooling solutions for non-road machines.

The research was not without challenges. During the experimental campaign, persistent and unexplained errors occurred with the battery cycler, which limited testing at higher rates and reduced the number of achievable transient cycles from the planned 50 to approximately 20. Despite extensive troubleshooting and discussions with the equipment supplier, the root cause could not be identified within the project timeframe. To address this, the thesis scope was carefully adapted. The focus was shifted toward detailed characterisation of the PCM-equipped module, including capacity, open-circuit voltage, and impedance measurements, as well as the feasible transient cycling tests. This ensured that the core research question could still be convincingly addressed despite the technical limitations.

Although the study focuses on a laboratory-scale battery module, its implications extend well beyond the experimental setup. The results demonstrate that PCM-based passive cooling can effectively manage battery temperatures during high-power events, such as fast charging and transient duty cycles typical of non-road machines, without the complexity of active thermal systems. In practice, this approach could be integrated into battery packs for construction and off-road equipment to prevent hot spots, enhance safety, and extend battery lifetime in harsh operating environments.

Looking ahead, the findings also point to clear directions for future research. Longer-duration transient cycling tests on both PCM and non-PCM modules would allow quantification of long-term degradation benefits. Further work could also explore optimisation of PCM materials, hybrid passive–active cooling concepts, and the development of electro-thermal models to support scaling the approach to full-size battery systems for non-road applications.

Through its experimental evaluation of PCM-based and conventional battery modules under regular charge–discharge conditions, and detailed transient cycle testing of the PCM-equipped module, Shruthi Meda’s Master’s thesis makes a valuable contribution to the Flex-CPT project. It demonstrates where passive thermal management offers clear benefits and where its limitations lie, supporting the broader transition toward cleaner, more reliable, and energy-efficient propulsion technologies for non-road mobile machines.