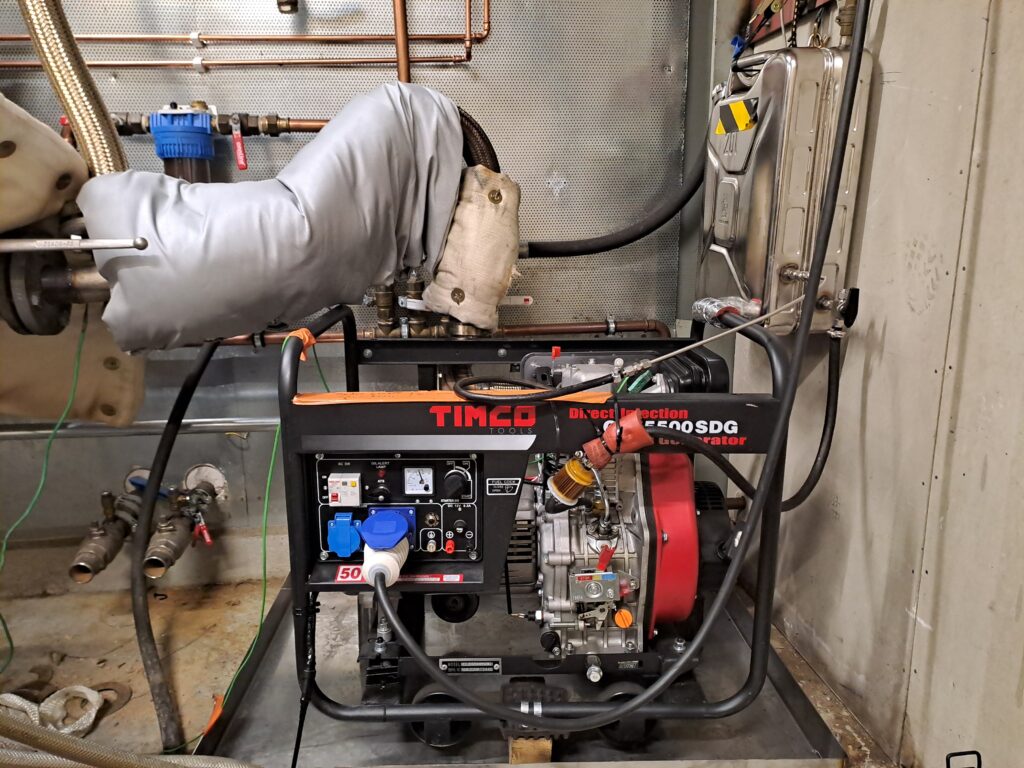

The first Flex-CPT project-related Master’s thesis by Anni-Rosa Apilainen examines emissions from diesel engines. The primary goal of the thesis, entitled “Characterization and control of ash from diesel engine exhaust” was to examine whether a diesel generator can produce particulate emissions comparable to those of a marine engine and the possibility to use the generator in further research related to Diesel Particulate Filters (DPFs). The primary goal of the study was to characterize the ash produced by the diesel engine. Diesel exhaust ash is a non-combustible residue resulting from the combustion of diesel fuel, lubricating oil, and engine wear.

The study provides detailed information on diesel particulate matter and exhaust ash, explaining their formation, sizes, and chemical composition. It also explores how DPFs work and why ash properties are meaningful for DPFs performance. The experiments used a diesel generator, combined with a special fuel blend to create ash, which was then analyzed using advanced microscopy and X-ray techniques. Additionally, gas emissions, soot levels, and particle number concentration and distribution were measured.

The analysis found that using lubricating oil doped fuel increased the number of particles in the exhaust gas by 152% (normalized particle number concentration). Different types of particles were identified, such as tiny fuel particles, spherical calcium containing oil particles, and clumped soot particles. Adding lubricating oil to the fuel helped reduce soot emissions presumably because the metal compounds in the oil made it easier for soot particles to burn.

The study concludes that fuel composition affects particulate emissions and their properties. The findings align with previous research and underscore the need for effective exhaust aftertreatment to reduce the environmental and health impacts of diesel emissions. Further research is recommended to explore the long-term effects of ash accumulation on DPFs, especially in conjunction with other aftertreatment systems.

The author Anni-Rosa Apilainen works as a researcher in VTT’s Transport Emission Control team. Her educational background is in Laboratory Engineering (TAMK), and she will graduate as Master of Science in Environmental Engineering from Tampere University at the turn of January and February. She spends her free time mostly in the gym, and in the summertime, she builds and rides a motorcycle.

– The most interesting part of the research work was the experimental activities. It was great to be involved through the whole process from building the measurement setup to analyzing the final ash samples. The ash was studied both quantitatively and qualitatively and especially the microscopy images and their analysis were very interesting. Participating in the study sparked an interest in nanoparticles and their behaviour, inspiring further research on how different factors, like temperature changes, affect exhaust gas particles also outside the master’s thesis, says Apilainen.

Based on findings made in this work, the properties of the particles generated by the diesel generator resemble to those obtained with marine engines using similar fuels. It can be concluded that instead of a large ship engine, a diesel generator can be effectively used in future studies to produce accelerated ash and to investigate the effects of ash on DPF. The study also poses an opportunity to develop even more accurate methods to measure ash concentration straight from the exhaust gas, which would be very beneficial, for example, in predicting DPF maintenance intervals or adjusting regeneration events.

After graduation Apilainen will continue to work as a research scientist at VTT and for a graduation gift for herself she plans to buy a new motorcycle.

The thesis is part of the Flexible Clean Propulsion Technologies project’s Work Package 4 “Aftertreatment Technologies for Multi-fuel Engine”, and more specifically, Task 4.4 “Rapid ageing procedure to ensure long-term ATS performance; focus on DPF and SCR”. Part of the study was also funded by the European Union (NextGenerationEU).

The thesis can be found: https://urn.fi/URN:NBN:fi:tuni-2024121811391

Figure 1. Insulation of exhaust lines with thermal wraps and thermal blankets. The exhaust wraps contain fiberglass, which is why the respirator was a must (main figure).

Figure 2. Diesel generator used as exhaust gas producer instead of marine engine