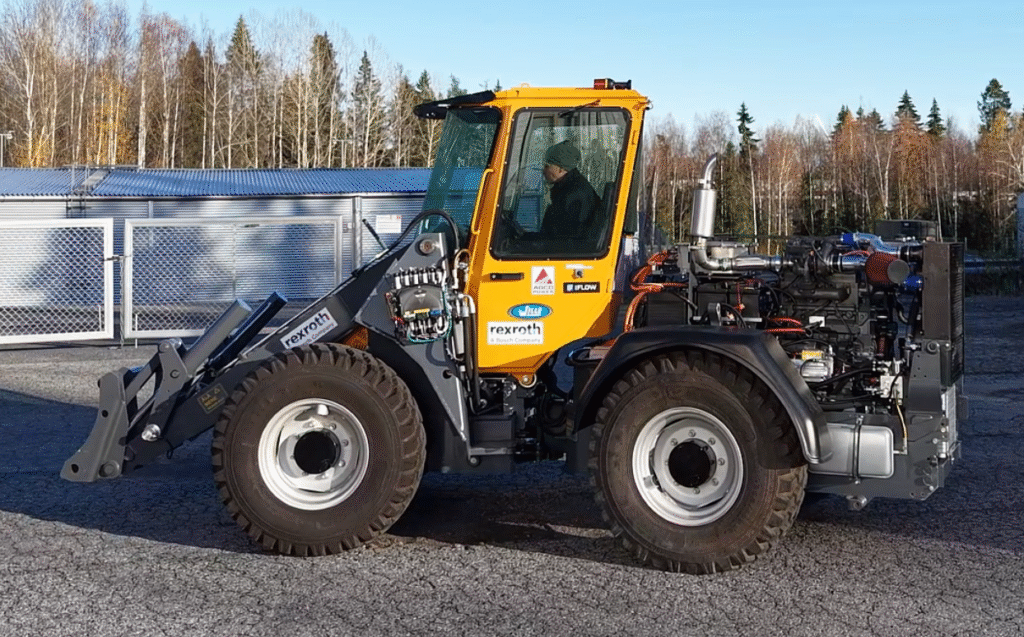

In the workshops at Tampere University, the hybrid test platform sWille took shape with deliberate purpose. It was designed to play a key role in the Flexible Clean Propulsion Technologies (Flex-CPT) project, which is uniquely positioned to overcome the challenges en route to zero-emission marine and off-road transport. sWille’s main purpose within Flex-CPT is to act as a test platform for the validation of simulation models created in WP5 – Hybrid solutions. With this real mobile work machine, the team will test and prove that the developed thermal simulation models and their parameters are valid. The simulation models cover the diesel-electric driveline, work functions and cooling system. “Having a real machine is essential,” says Dr. Petteri Multanen. “With sWille, we can finally validate our hybrid-system simulation models in authentic operating conditions, and that makes all the difference for credible research outcomes.”

The development journey was full of notable moments and some steep challenges. The key moment was the first full-scale test drive of sWille outdoors and all subsystems operating as planned. Major challenges along the way included long delivery times of key components, the development of a complex control system and through it, especially the communication between electric components from different manufacturers. On the other hand, the team learned a great deal and gained experience of electrification and hybridization of mobile work machines. “Seeing sWille complete its first full-scale outdoor test was a milestone for the whole team,” Dr. Multanen reflects. “Despite long delivery times and the complexity of integrating components from different manufacturers, the experience strengthened our expertise in electrification and hybridisation of mobile work machines.”

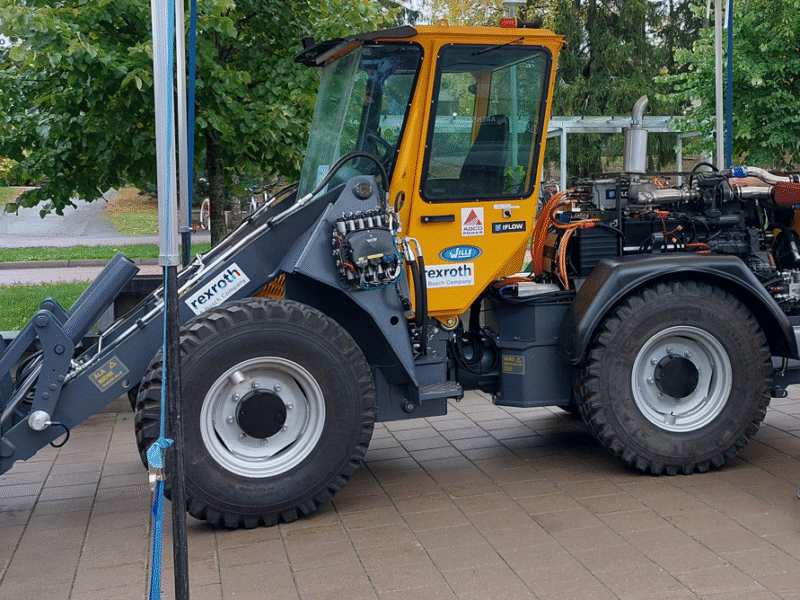

What makes sWille unique is its configuration as a diesel-electric series hybrid wheel loader, designed and built on the frame of a standard Wille wheel loader from Wille Machines. The hydrostatic transmission of the original machine is now replaced with electric transmission using two electric motors, and both work and auxiliary hydraulic pumps are also driven with two electric motors. The machine can be operated using a diesel motor and generator to produce electricity for the motors or to charge the 360 V batteries and use the machine battery-powered.

In addition the boom operation of sWille is implemented in a unique way. Its hydraulics are realised with Digital Flow Control Units (DFCUs) and include two hydraulic accumulators. The DFCUs consist of forty digitally controlled valves instead of two load-sensing valves of the original machine. These digital hydraulic valve sets enable the controlling of working actions with clearly lower energy losses than with traditional valves. With the hydraulic accumulators, the setup enables the recovery of hydraulic energy during lowering of the bucket which can then be utilised in following work functions.

sWille is perfectly suited to support the research of Flex-CPT. The components of its driveline and work hydraulics were already modelled in the earlier Clean Propulsion Technologies (CPT) project. And as it is a hybrid machine, it has a lot of components with different optimal operating temperatures which poses the challenge for thermal management that Flex-CPT will solve.

A range of partners from the Flex-CPT consortium contributed directly to the development and implementation of sWille. AGCO Power provided the diesel engine, engine communication, and control. Bosch Rexroth supplied the electric motors, inverters, and their control. Proventia delivered the batteries and the thermal shields for the diesel engine. In addition to this direct component-related support, all company representatives contributed valuable practical know-how of mobile machines and their subsystems.

Looking ahead, the next step is to prepare sWille for tests and measurements needed in Flex-CPT for validating thermal simulation models. That means using the machine in similar operating conditions as in simulations and ensuring that, for example, the thermal behaviour of sWille components is consistent with the simulated results. This will enable the correct component parameters to be defined and the accuracy of the simulation models confirmed.