Iida Sieranen’s Master’s thesis investigates how renewable and blended fuels interact with carbon steel, a common engine material, a topic that supports the FLEX-CPT project’s efforts to ensure the safe and efficient use of future fuels. The thesis, titled “Fuel-induced corrosion: Analysis of temperature effect on carbon steel immersed in various fuels,” contributes to the broader aims of Work Package 3 (WP3), which focuses on evaluating the feasibility and material compatibility of carbon-neutral fuels in marine and non-road applications.

WP3 is led by Katriina Sirviö, University of Vaasa. One of the central objectives of the thesis was to improve the university’s laboratory method for assessing corrosion, enabling more reliable and flexible testing of fuel-material interactions.

“I recently graduated from the University of Vaasa with a Master of Science degree in Energy Technology,” Sieranen explains. “I also hold a degree in Biomedical Laboratory Science and Health and Social Care Management. My career started in healthcare, where I worked for over 10 years. That background helped me approach this thesis with a systematic and research-oriented mindset.”

Her transition into energy research highlights the kind of interdisciplinary perspective increasingly valued in clean technology development – blending precision, experimentation, and applied methodology.

The first objective of the thesis was to develop a more robust immersion test for the University of Vaasa’s Fuel Laboratory. Sieranen focused on improving several technical aspects of the procedure, such as fuel preparation, metal sample design, and the attachment method used to suspend carbon steel samples in fuel. A smaller sample size not only enabled more accurate weighing before and after critical testing for measuring corrosion rate but also allowed for advanced surface analysis using scanning electron microscopy (SEM).

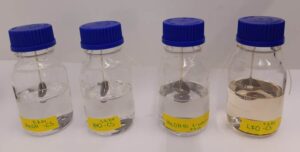

Picture of fuel samples (MeOH, RD, blend and LFO) before the immersion test at temperature of 40 ̊C.

One of the key innovations in Sieranen’s thesis was the introduction of a temperature-controlled immersion setup, supported by a newly installed heating cabinet. This setup enabled corrosion testing under stable thermal conditions relevant to the operating environment. The use of smaller carbon steel samples also contributed to the improved method, as it enabled both corrosion rate calculations and detailed SEM imaging. Together, these developments significantly strengthened the laboratory’s ability to assess fuel-material interactions.

Once the test method was refined, the second objective of the thesis was to apply it across multiple fuel types at two temperature conditions: 23°C and 40°C. The fuels included renewable diesel (RD), light fuel oil (LFO), methanol (MeOH), and a blended fuel stabilized with 1-octanol.

Interestingly, the results showed no significant corrosion or fuel contamination at either temperature. This finding adds to the body of knowledge suggesting that certain low-emission fuels can be safely used with carbon steel, which is a positive sign for their wider application in engine systems.

One of the more unexpected challenges came early in the process. “Finding carbon steel samples with the exact dimensions and known elemental composition was difficult,” Sieranen recalls. “I contacted several regional companies before securing a suitable supplier.”

Looking ahead, Sieranen sees strong potential in both the testing method and its applications. The approach can be adapted to study different fuel blends, additives, temperatures, and exposure durations. “As the EU aims to phase out fossil fuels by 2050, and shipping remains one of the largest sources of greenhouse gas emissions, the move toward alternative fuels must be supported by robust material compatibility research,” she says.

Sieranen is now seeking opportunities in the energy sector and plans to pursue doctoral studies. Her thesis not only advances laboratory capabilities but also strengthens the foundational research needed to guide future fuel adoption in marine and off-road transport, which is a key pillar of the FLEX-CPT project’s vision for sustainable propulsion systems.